Together for An Electric Future.

Power tools are essential for both professionals and DIY enthusiasts. They help us work more efficiently, whether it's cutting, drilling, sanding, or grinding. However, like all machinery, power tools are susceptible to wear and tear over time. When a tool malfunctions, it can stop you in your tracks and cause unnecessary delays. The key to avoiding downtime and keeping your projects on schedule is knowing how to troubleshoot and fix common issues.

In this article, we’ll explore the most common power tool problems and provide practical, actionable tips on how to diagnose and fix them. Whether you're dealing with a tool that won't turn on, poor performance, unusual smells, or even smoke and sparks, this guide will help you get back to work with minimal interruption.

One of the most frustrating problems with power tools is when they simply won't start. This issue can be caused by several factors, including electrical problems, a malfunctioning switch, or a dead battery. Here's how to troubleshoot:

The first step is to verify that the power tool is properly connected to a functioning power source. For corded tools, inspect the power cord for any visible damage such as frays, cuts, or kinks. If the cord is damaged, it must be replaced to restore power flow.

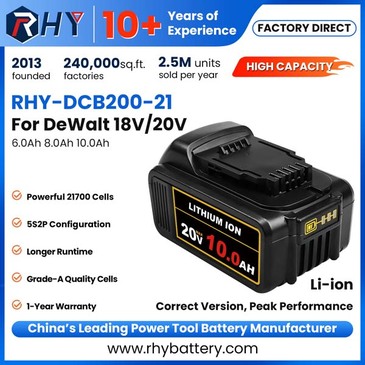

For cordless tools, check the battery. Ensure that it is fully charged and correctly inserted. If the battery is old or not holding a charge, it may need replacing.

The switch itself can also wear out over time. If there is no power reaching the tool, and the cord and battery are fine, the switch could be the culprit. Test the switch with a multimeter to see if it’s working properly. If not, it will need to be replaced.

If the power source and switch are functioning correctly, you may have an internal wiring issue or short. Use a multimeter to check for continuity across various components like the motor. This can help you identify which part needs attention.

Another common issue is when a tool turns on but doesn’t seem to have the same power or performance as before. This typically points to worn-out parts, such as carbon brushes, or a damaged motor.

Carbon brushes conduct electricity to the motor, and over time they can wear down. When this happens, the motor will lose power. Inspect the brushes for any signs of excessive wear, such as shortened length or uneven contact surfaces. If they are worn, they should be replaced to restore proper performance.

In some cases, reduced power could indicate a more severe problem with the motor, such as damaged windings or other internal issues. If the motor appears damaged, it may need professional repair or replacement.

Overheating can also lead to poor performance. Check the tool’s air vents to ensure they’re not blocked by dust and debris. Cleaning the vents regularly will help prevent overheating, which can decrease power output.

If your tool starts emitting a burning smell or excessive heat, it’s important to shut it off immediately to avoid further damage. A burning smell often points to an issue with the motor, drive belt, or electrical components.

For tools that rely on a drive belt (such as sanders or planers), a burning smell could indicate that the belt has snapped or is slipping. This friction causes heat buildup, leading to the smell. Inspect the belt for any signs of wear, cracks, or breakage and replace it as necessary.

Power tools generate heat during use, especially if they’ve been running for long periods or under heavy load. If the tool has been used intensively, allow it to cool down for at least 30 minutes before continuing work. Overheating can damage internal components, so if the tool continues to overheat even after cooling, there could be a more serious issue with the motor or internal wiring.

In rare cases, a burning smell can result from overheating electrical components, such as capacitors or wiring. If the tool has been exposed to excessive heat or moisture, these parts can degrade and cause malfunction. If you're unable to identify the issue, it might be time to take the tool to a professional for further inspection.

Hearing high-pitched squeals or screeching sounds from your power tool can be a sign of several different issues, most of which are related to improper lubrication or gear problems.

Many power tools have internal gears or mechanisms that require regular lubrication to function properly. If you hear a high-pitched noise, it could mean that the tool’s moving parts are dry and rubbing against each other. Consult the tool’s manual to determine the correct lubricant and apply it accordingly.

If your tool has a gear mechanism, such as a drill or impact driver, inspect the gears for wear or damage. A gear switch that is stuck between positions could also cause unusual sounds. Try manually shifting the gear to see if the noise stops. If the gears are damaged, they will need to be replaced.

One of the most alarming problems is when your power tool begins emitting smoke or sparks. This is a serious issue that requires immediate attention.

If your power tool starts smoking or sparking, shut it off and unplug it (or remove the battery if cordless). Continuing to use the tool in this condition could lead to a fire or cause permanent damage to the internal components.

In dusty environments, fine particles can get into the tool’s vents or motor and cause overheating, leading to sparks. Clean out any dust or debris from the tool to prevent this from happening.

Sparking can also be caused by worn-out motor brushes. These brushes allow the electrical current to flow to the motor, and when they wear down, they can create excessive sparking. Inspect the brushes and replace them if necessary.

Frayed or damaged wiring can also cause sparks. If you notice exposed wires or damaged insulation, the wiring will need to be replaced immediately.

Proper maintenance and troubleshooting are key to extending the life of your power tools and ensuring that they perform at their best. By diagnosing common problems such as reduced power, overheating, unusual noises, and electrical malfunctions, you can fix most issues quickly and get back to work. Regular inspections, cleaning, and part replacements are essential to keeping your tools in top shape.

If your these common tips don’t fix your issues, or if you’re still unsure of the best course of action, contact RHY today. We have an extensive line of power tools that will do the job!

Learn about our Industrial Solutions or give us a call at +86 755 2829 5998.